In the realm of heavy machinery, the efficiency and reliability of hydraulic systems are paramount, making the choice of a hydraulic cylinder for your equipment a critical decision. According to a recent report by MarketsandMarkets, the global hydraulic cylinder market is projected to grow from USD 14.3 billion in 2021 to USD 20.1 billion by 2026, indicating a significant demand for advanced hydraulic solutions in various industries, including construction, agriculture, and manufacturing. Hydraulic cylinders play a pivotal role in converting hydraulic energy into mechanical force, thereby ensuring optimal machine performance. Selecting the best hydraulic cylinder for your specific needs not only enhances the productivity of your machinery but also contributes to cost savings through improved operational efficiency. This blog will explore the ten best hydraulic cylinders available, providing insights into their specifications, applications, and what makes them stand out in a competitive marketplace.

When selecting hydraulic cylinders for heavy machinery, several key features should guide your decision. First and foremost, consider the cylinder's bore size and stroke length, as these determine the power and reach necessary for your specific application. A larger bore can generate more force, while an appropriate stroke length ensures that the cylinder can adequately accommodate the required range of motion for your machinery.

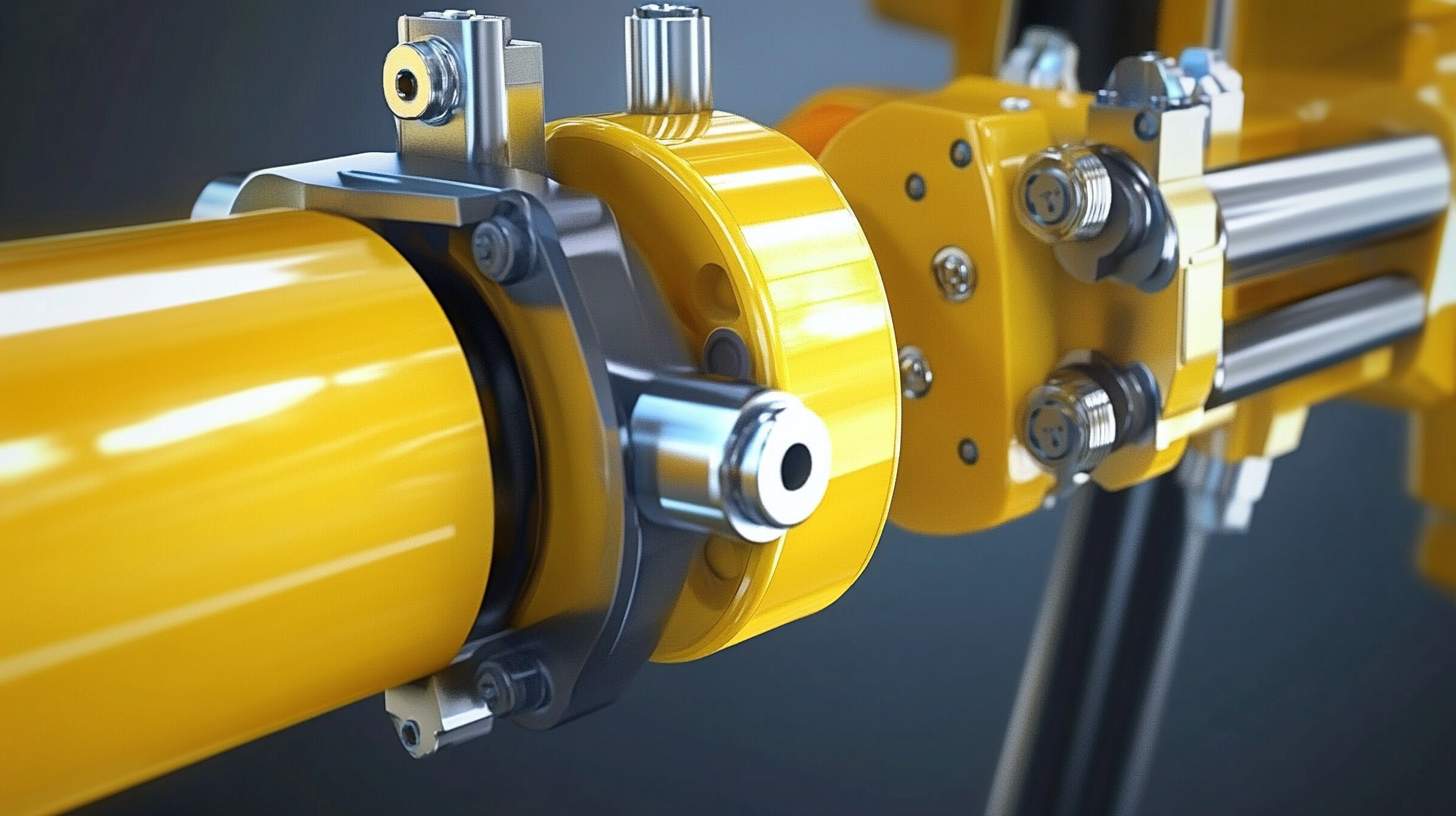

Another crucial factor is the cylinder's construction and materials. Opt for cylinders made from durable materials that can withstand harsh environments and heavy loads. Additionally, look for features such as corrosion resistance and the ability to operate under high temperatures, as these attributes enhance the longevity and reliability of the equipment.

Finally, pay attention to seal design, as high-quality seals minimize leakage and maintenance needs, ensuring optimal performance in demanding situations. Taking these features into consideration can significantly improve the efficiency and effectiveness of your hydraulic systems.

When selecting hydraulic cylinders for heavy machinery, understanding the technical specifications is crucial for optimal performance. According to a report from the Global Hydraulic Cylinder Market, the demand for hydraulic cylinders is projected to grow at a CAGR of 6.5% from 2021 to 2026, underscoring their significance in construction and manufacturing sectors. Key specifications such as bore diameter, rod diameter, stroke length, and maximum pressure ratings significantly impact a cylinder's efficiency and durability. For instance, cylinders with a larger bore diameter can handle higher loads, making them suitable for heavy-duty applications.

One of the top contenders in the industry is the Parker 2H Series, known for its robust structure and impressive operating pressure of up to 3,000 PSI. Additionally, reports indicate that cylinders equipped with advanced sealing technologies can extend service life by 20-30%, which is essential for reducing downtime in machinery operations. The importance of integrating smart sensor technology into hydraulic systems is also highlighted in recent industry studies, showing that real-time monitoring can enhance system efficiency and provide predictive maintenance capabilities. These specifications and technological advancements are vital for operators seeking reliability and performance in their heavy machinery.

When selecting hydraulic cylinders for heavy machinery, performance metrics play a crucial role in determining efficiency and productivity. According to a report by the International Journal of Hydraulic Engineering, factors such as stroke length, load capacity, and response time significantly affect the usability of hydraulic systems. For example, cylinders with a longer stroke length can enhance the machine's range of motion, making them ideal for applications in construction and mining where precision and reach are paramount. A recent industry analysis indicates that cylinders with a stroke length exceeding 60 inches yield a 15% increase in operational efficiency compared to shorter counterparts.

Additionally, load capacity is another vital performance metric. The American Society of Mechanical Engineers (ASME) suggests that selecting hydraulic cylinders capable of withstanding at least 1.5 times the intended load can provide a safety buffer that is essential in heavy-duty applications. High-capacity cylinders, particularly those rated above 20 tons, are becoming increasingly popular in industries requiring robust lifting solutions. A comparative study in the Hydraulic Systems Review highlighted that advanced materials, such as high-strength alloy steels, can further enhance performance, achieving a reduction in weight while maintaining strength and reliability, ultimately leading to improved machine performance in demanding environments.

When it comes to heavy machinery, properly installing hydraulic cylinders is crucial for optimal performance and safety. According to a recent industry report by the International Journal of Engineering Research, approximately 30% of hydraulic cylinder failures can be traced back to improper installation techniques. This statistic highlights the importance of adhering to best practices, starting with selecting the right size and type of cylinder for your specific machinery needs. Ensure that the cylinder's specifications match your machine's operational requirements to prevent undue stress and potential failure.

The installation process itself requires careful attention to detail. Begin by thoroughly cleaning the mounting surfaces and ensuring they are free of debris. According to a study by the Mechanical Engineering Society, over 25% of installation errors occur due to inadequate surface preparation. Align the hydraulic cylinder accurately, taking care to adjust for any misalignment that could lead to premature wear. Once in position, use the correct torque specifications for bolts to secure the installation, as improper torque can lead to leakage or cylinder failure. Following these guidelines will not only enhance the durability of your hydraulic systems but also improve overall safety in your operations.

| Cylinder Type | Bore Size (inches) | Rod Diameter (inches) | Stroke Length (inches) | Max Pressure (psi) | Material | Weight (lbs) |

|---|---|---|---|---|---|---|

| Double Acting | 4 | 2 | 10 | 3000 | Steel | 45 |

| Single Acting | 5 | 3 | 12 | 2500 | Aluminum | 30 |

| Telescopic | 6 | 4 | 16 | 4000 | Steel | 60 |

| Mini Cylinder | 2 | 1 | 5 | 1500 | Aluminum | 10 |

| Heavy Duty | 8 | 5 | 20 | 5000 | Steel | 85 |

Maintaining hydraulic cylinders is crucial for maximizing their lifespan and ensuring the reliable performance of heavy machinery. Regular maintenance practices, including routine inspection, can significantly extend the life of these components. Just as machine shed doors and heavy haul trailers require careful upkeep, hydraulic systems benefit from a preventative maintenance approach. This involves checking for leaks, ensuring proper lubrication, and monitoring seals for wear, which helps prevent catastrophic failures that could lead to costly repairs.

In addition to visual inspections, operators should also maintain cleanliness around hydraulic cylinders, as dirt and debris can lead to damage over time. After using machinery, especially in muddy or harsh environments, cleaning the equipment thoroughly is essential. This attention to cleanliness not only protects the machinery but also ensures that vital components, such as hydraulic cylinders, remain in peak condition. By implementing these maintenance tips, operators can ensure that their hydraulic systems operate smoothly and efficiently, ultimately leading to enhanced productivity and reduced downtime.

This bar chart displays the load capacity of various hydraulic cylinders, demonstrating their performance capabilities. Proper maintenance can help extend their lifespan and ensure optimal functioning in heavy machinery.