Choosing the right long hydraulic cylinder is crucial for the success of any project involving heavy machinery and equipment. According to a recent industry report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach USD 15.7 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth underscores the increasing reliance on hydraulic systems across various industries, including construction, manufacturing, and agriculture. Selecting a long hydraulic cylinder that meets specific project requirements can significantly enhance efficiency, safety, and performance. Factors such as stroke length, bore diameter, and pressure ratings play a pivotal role in this decision-making process. As we delve into the best practices for selecting the ideal long hydraulic cylinder, it's essential to consider these parameters to ensure your project's success and sustainability in an increasingly competitive market.

When selecting the right long hydraulic cylinder for your project, it is essential to understand the specific requirements and challenges you are facing. Whether it's for infrastructure projects such as bridge replacements or large-scale renovations like the Panama Canal expansion, the appropriate choice of hydraulic cylinder directly impacts the efficiency and effectiveness of your work. Data shows that hydraulic systems, when designed with the right specifications, can lead to a 20-30% increase in operational efficiency.

Tip 1: Always analyze the load requirements and pressure ratings necessary for your project. Custom hydraulic cylinders can sometimes be built from off-the-shelf components, providing flexibility and reducing lead times. This adaptability is crucial in the fast-paced field of construction and engineering.

Furthermore, with emerging technologies in hydraulic systems, such as electrification and energy efficiency improvements, it is vital to keep your project aligned with industry advancements. For instance, reports indicate that transitioning to energy-efficient hydraulic systems can reduce operational costs significantly.

Tip 2: Consider not just the immediate requirements but also the long-term sustainability of hydraulic solutions. Features such as corrosion resistance and maintenance frequency can enhance the lifespan of your hydraulic cylinders. This is particularly relevant for projects like the recent bridge developments where environmental factors can play a major role in the performance of hydraulic equipment.

When selecting a long hydraulic cylinder for your project, evaluating load capacity and pressure specifications is crucial. Load capacity refers to the maximum weight a cylinder can effectively lift or support, and it is integral to not only the functionality but also the safety of the operation. According to the International Energy Agency (IEA), improper load assessments can lead to failures, which often result in significant operational downtime and financial loss. For example, accurately determining the dynamic load capacity—often distinguished from static load capacity—ensures the cylinder can handle both constant and transient loads encountered during operations.

Moreover, understanding pressure specifications is a key aspect of this selection process. Hydraulic cylinders typically operate within a range of pressure limits; exceeding these can cause catastrophic failures. A report from the National Fluid Power Association (NFPA) indicates that cylinders with a rated pressure of up to 3000 PSI are prevalent in construction and mobile machinery applications. It’s imperative to match the cylinder’s pressure rating with the system requirements to enhance both performance and longevity. Therefore, while considering load and pressure, project managers can significantly reduce the risk of system failure and improve overall efficiency.

When selecting a long hydraulic cylinder, one of the most critical considerations is the choice of material. The material not only influences the cylinder's strength and durability but also its performance under various operating conditions. For projects that will see extreme pressures or harsh environmental influences, materials such as high-strength steel or specialized alloys may be necessary. These materials provide enhanced resistance to wear and tear, ensuring a longer lifespan and reducing the risk of failure during operation.

In addition to strength, the material's compatibility with hydraulic fluids is vital. Certain metals may corrode or degrade when in contact with specific fluids, leading to potential system failures. Therefore, selecting a material that offers chemical resistance, alongside mechanical strength, is paramount for optimal performance. Manufacturers often provide detailed specifications regarding material properties, making it essential to analyze these data points to make an informed decision. Choosing the right material not only boosts the operational efficiency of your hydraulic system but also ensures safety and reliability over time.

| Material | Tensile Strength (MPa) | Weight (kg/m) | Corrosion Resistance | Cost ($/kg) |

|---|---|---|---|---|

| Carbon Steel | 400 | 78.5 | Low | 1.0 |

| Stainless Steel | 520 | 80 | High | 3.0 |

| Aluminum Alloy | 350 | 27 | Medium | 2.5 |

| Titanium Alloy | 900 | 45 | Very High | 7.0 |

| Composite Materials | 600 | 18 | High | 5.5 |

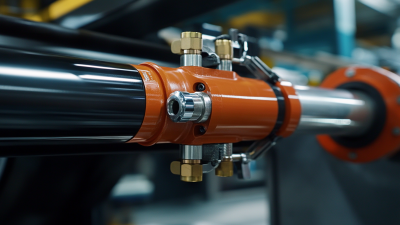

When selecting a long hydraulic cylinder for your project, cylinder design and mounting options are critical factors that can

significantly influence performance and efficiency. Understanding the different designs available—such as single-acting vs. double-acting cylinders—will help you choose the right option based on your application’s specific needs.

For instance, if your project requires force in one direction with a return spring mechanism, a single-acting cylinder might be sufficient. However, for applications needing consistent force in both directions,

a double-acting cylinder is essential.

Mounting options also play a vital role in the effectiveness of hydraulic cylinders. Common mounting types include trunnion mounts, pin mounts, and fixed mounts, each offering varying degrees of flexibility and stability.

Choosing the right mount influences not only the ease of integration into your machinery but also the overall dynamic performance of the cylinder under operating conditions.

By carefully evaluating both the design and mounting options, you can ensure that your selected long hydraulic cylinder meets the demands of your project while maximizing its lifespan and operational efficiency.

When selecting the right long hydraulic cylinder for your project, consulting with experts and manufacturers is crucial for making informed decisions. These professionals possess in-depth knowledge about various hydraulic systems and can help you understand the specific requirements for your application. By discussing your project goals, they can provide tailored recommendations, ensuring that you select the most suitable cylinder based on dimensions, load capacity, and environmental conditions.

Moreover, collaborating with manufacturers allows you to gain insights into the latest technological advancements in hydraulic systems. This partnership can be instrumental in enhancing operational efficiency and longevity of your equipment. Such expertise not only mitigates risks associated with subpar choices but also ensures compliance with industry standards. By leveraging the insights of seasoned consultants and manufacturers, you can significantly elevate the success of your project, bringing your hydraulic applications to a new level of performance and reliability.

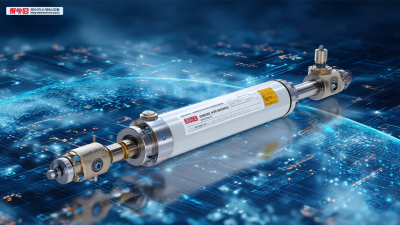

This chart represents the key parameters to consider when selecting a long hydraulic cylinder for your project. Each bar indicates the typical values you may encounter in the market, helping you make a more informed decision.