In the realm of hydraulic equipment, aftermarket solutions are a topic of great interest. John Smith, a renowned expert in hydraulic systems, emphasizes, "Aftermarket Hydraulic Cylinders offer versatility that OEMs may lack." This statement captures the essence of why many equipment managers are turning to aftermarket options.

Aftermarket Hydraulic Cylinders provide unique benefits. They often come with customizable features. Such cylinders can adapt to various equipment needs without breaking the bank. Achieving efficiency and cost-effectiveness can be a challenge. However, aftermarket products frequently surprise users with their performance and longevity.

Choosing aftermarket parts does require careful consideration. Some may worry about quality or compatibility issues. It's vital to research suppliers and their offerings. The risk of choosing the wrong product can be daunting. Yet, with informed decisions, aftermarket hydraulic solutions can enhance any operational setup.

Aftermarket hydraulic cylinders offer several advantages for equipment performance. These cylinders are often more affordable than original equipment manufacturer (OEM) options. This cost-effectiveness does not mean sacrificing quality. Many aftermarket cylinders meet or exceed industry standards. They provide reliable performance, which is essential for efficient operation.

Durability is another key benefit. Aftermarket hydraulic cylinders are built to withstand tough conditions. For instance, they often feature robust materials and advanced engineering. This can lead to less downtime and reduced maintenance costs. Over time, choosing aftermarket options can translate to significant savings. However, quality can vary among suppliers. Always conduct thorough research before making a purchase.

Flexibility is an essential factor too. Aftermarket parts may offer a wider range of specifications. This allows for customization based on specific equipment needs. As equipment evolves, the aftermarket can quickly adapt to new demands. Yet, it’s crucial to ensure compatibility with existing systems. Finding the right balance can be challenging, but it is necessary for optimal performance.

| Feature | Aftermarket Hydraulic Cylinders | OEM Hydraulic Cylinders |

|---|---|---|

| Cost | Generally lower cost | Higher price due to brand |

| Availability | Readily available from multiple suppliers | Limited supply, may require long lead times |

| Customization | Can be easily customized for specific needs | Limited customization options |

| Performance | High performance with proper selection | Guaranteed performance as per OEM standards |

| Warranty | Varies by supplier | Typically comes with a manufacturer warranty |

| Lead Time | Shorter lead times for common models | Longer lead times for parts |

Aftermarket hydraulic cylinders offer a cost-effective alternative to original equipment manufacturer (OEM) options. Many users find that these cylinders perform well, often at a fraction of the price. They can help businesses save significant amounts in repair and maintenance costs. Some aftermarket products may not meet the exact specifications of OEM parts, but they can still function effectively for various applications.

Choosing aftermarket hydraulics can be a gamble. Quality varies widely among manufacturers. It’s essential to do your homework. Look for reputable suppliers with positive reviews. Sometimes, the lower price comes with trade-offs, such as shorter lifespans or inconsistent performance. Companies must weigh these risks against their budget constraints.

In many cases, aftermarket options can lead to unexpected benefits. They frequently offer customization possibilities that OEM parts do not. This flexibility can be crucial for unique machinery setups. However, the potential for compatibility issues should not be overlooked. It’s wise to consult industry experts when selecting components. Understanding the balance between cost and quality is vital for long-term success.

This chart illustrates the average cost of OEM hydraulic cylinders compared to aftermarket options. As shown, aftermarket hydraulic cylinders are significantly more cost-effective, with an average price of $800 compared to $1200 for OEM cylinders.

Aftermarket hydraulic cylinders offer a wide range of customizability. These solutions cater to specific equipment needs, ensuring efficiency and performance. According to industry reports, nearly 70% of customers prefer tailored products that fit their operational demands. It’s significant, as generic cylinders often fall short.

Customization can include different bore sizes, strokes, and mounting configurations. This flexibility allows companies to optimize their machinery for unique applications. For instance, a mining operation may need a robust cylinder that can withstand harsh environments. Standard options may not thrive in such conditions. A report by the Hydraulic Institute noted that customized cylinders could enhance equipment lifespan by 30% or more.

While aftermarket options can be beneficial, they sometimes lack uniform standards. Quality can vary widely across different suppliers. Research suggests that 25% of users report issues with installation or performance. This highlights the importance of choosing reliable vendors. Not all aftermarket products meet the same benchmarks. Users must conduct thorough evaluations to mitigate risks.

Aftermarket hydraulic cylinders have gained popularity due to their quality and reliability. Manufacturing standards have improved significantly over the years. According to a recent industry report, the aftermarket sector accounted for nearly 40% of the global hydraulic cylinder market. This reflects a growing trust in aftermarket solutions.

Quality control is essential in this market. Manufacturers often subject cylinders to rigorous testing. This ensures they meet the highest operational standards. Many cylinders undergo pressure tests that exceed original equipment specifications. It’s not merely about meeting expectations; it’s about surpassing them.

**Tip:** Always check the certifications of the manufacturer. Certifications can indicate levels of quality assurance.

Durability is another key factor. Aftermarket cylinders often use superior materials. This can extend their lifespan considerably. A study has shown that high-quality aftermarket cylinders can last up to 30% longer than standard options. However, not all aftermarket products are created equal. Some manufacturers may cut corners to reduce costs.

**Tip:** Consider warranty offers before purchase. A longer warranty can suggest greater manufacturer confidence.

Choosing aftermarket hydraulic cylinders means recognizing both risks and benefits. A careful selection can lead to substantial cost savings and enhanced performance. The market is competitive, and being informed is crucial. Quality does matter, and the right choice can lead to reliable equipment performance.

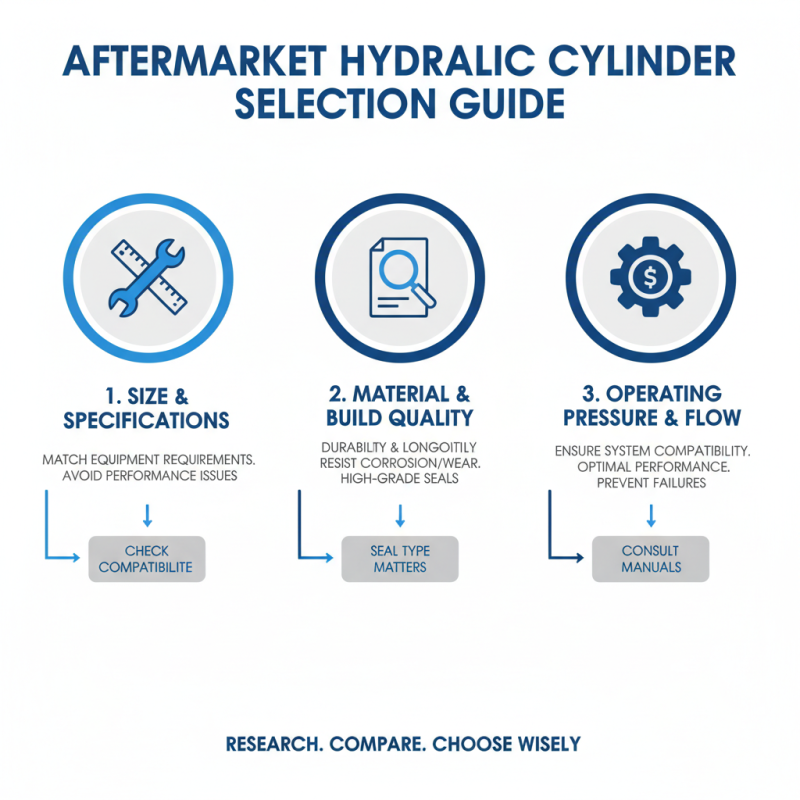

When selecting aftermarket hydraulic cylinders, several factors come into play. First, consider the cylinder's size and specifications. Ensure that it matches your equipment's requirements. If it’s too large or too small, performance issues may arise. Checking compatibility is crucial. Research the specifications thoroughly to avoid mistakes.

**Tips:** Measure your current cylinders carefully. Consult technical manuals for your equipment. A mismatch can lead to costly setbacks.

Next, assess the quality of materials used in the hydraulic cylinders. High-quality steel or aluminum can enhance durability. However, some aftermarket options may skimp on quality. Be cautious of overly cheap products. They might save money initially but fail quickly under pressure.

**Tips:** Look for reviews or ratings online. Speak to other users about their experiences. It’s best to have real-world insights.

Finally, consider the warranty and support offered. A reliable aftermarket cylinder often comes with a solid warranty. This reflects confidence in product quality. Lack of support can be frustrating when problems arise. Always verify what’s included in the purchase.

**Tips:** Reach out to manufacturers for clarification. Understand the warranty details before making a decision. A little extra research can save future headaches.