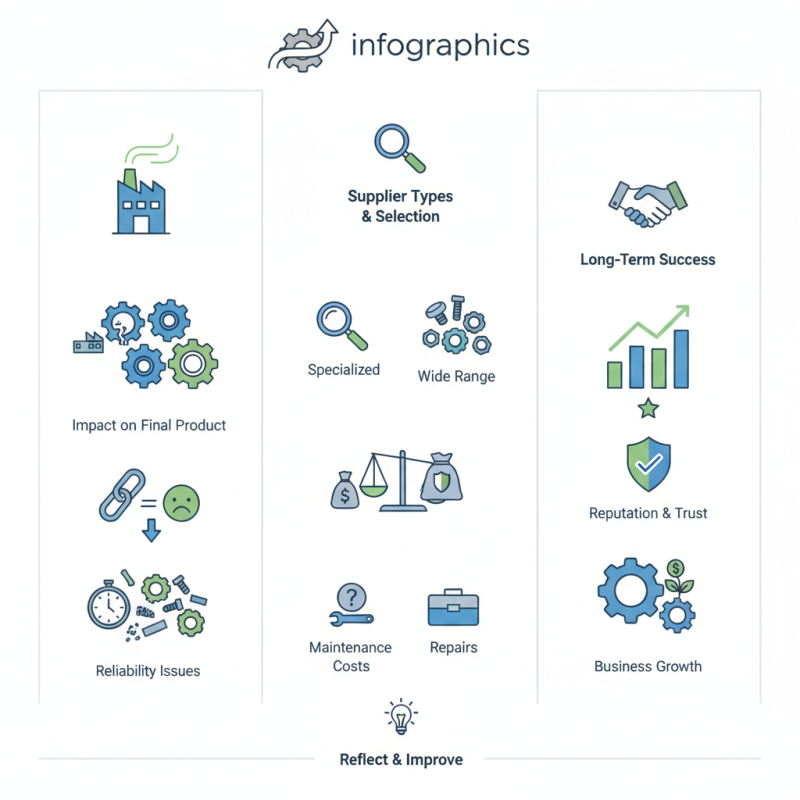

Choosing the right mechanical parts suppliers is crucial for any business. The quality of the parts directly impacts the final product. If the suppliers are unreliable, production can suffer. Delays and defects can lead to lost revenue and damaged reputations.

mechanical parts suppliers come in various forms. Some are specialized, while others offer a wide range of products. It can be tempting to go for the cheapest option. However, this decision might come with hidden costs. Poor quality parts can increase maintenance costs and lead to more frequent repairs. Reflecting on past supplier choices can reveal patterns. Have you faced issues with inconsistent quality? Did you lose clients due to delays?

When selecting mechanical parts suppliers, consider their reliability and reputation. Researching potential partners is vital. A good supplier not only provides parts but also supports your business growth. Ultimately, the right choice will contribute to long-term success.

Mechanical parts suppliers play a crucial role in various industries. They provide essential components that ensure smooth production processes. Quality parts can enhance machinery performance. On the other hand, subpar components can lead to malfunctions. Choosing a reliable supplier is not always straightforward. Many businesses overlook the importance of vetting suppliers closely.

Effective communication is vital in this relationship. Suppliers who understand specific industry needs can offer tailored solutions. This can streamline operations significantly. However, not all suppliers will take the time to understand these needs. Misalignment often leads to delays and increased costs. Businesses must recognize the need for clear expectations and feedback.

Trust is another important aspect. Building a relationship with a supplier takes time. Customers must be willing to invest in that relationship. Often, suppliers may fail to deliver on time or may provide incorrect parts. Reflecting on past experiences can help improve future selections. Regular assessments can ensure that standards are maintained.

When it comes to mechanical parts, quality assurance is crucial. Suppliers play a significant role in this area. A reliable supplier can ensure that parts meet specific standards. This, in turn, affects product performance. Poor-quality components may lead to malfunctions or inefficiencies. These failures can be costly in terms of both time and resources.

Choosing a supplier involves more than just cost considerations. The right supplier will provide robust testing and validation methods. Communication is vital, too. Clear feedback loops can help catch defects before they escalate. However, some suppliers may lack proper procedures. This can lead to inconsistencies and quality issues.

Reflecting on these aspects is important. A product’s success often hinges on its parts. When suppliers do not deliver quality, brands suffer. Companies should regularly assess their supplier relationships. This evaluation can reveal potential risks and areas for improvement. With the right partners, businesses can enhance their product reliability.

Choosing the right mechanical parts supplier can significantly impact cost efficiency. According to a recent industry report, businesses can save up to 25% on production costs by selecting the right vendor. However, many companies overlook this essential step. Delays and quality issues often arise, leading to higher costs in the long run.

Identifying budget-friendly suppliers is crucial. Companies need to analyze their expenses and develop relationships with multiple suppliers. Diversifying suppliers can lead to better pricing and improved quality. A study from a logistics firm shows that firms using multiple suppliers experience a 15% reduction in procurement costs. However, it's essential to remain vigilant. Over-reliance on one supplier can lead to price hikes and reduced quality.

Tip: Always request samples before making bulk orders. This step helps ensure quality meets your standards.

Another effective strategy is to negotiate contracts regularly. Suppliers may offer better rates for long-term commitments but avoid locking in unfavorable terms. Review each contract carefully. Keeping an eye on market trends helps re-evaluate supplier performance.

Tip: Regularly assess supplier performance metrics. This evaluation can prevent future issues and keep costs low.

Choosing the right mechanical parts suppliers can significantly impact your operations. One crucial aspect is supply chain reliability. Timely deliveries are not just a luxury; they are essential for maintaining workflow. When parts arrive late, production lines halt. This leads to losses that can be hard to recover from.

Think about a missed deadline. A critical component doesn’t arrive as scheduled. This could push back project timelines significantly. Even minor delays can escalate costs and frustrate teams. The stress of managing unforeseen issues can cloud judgment and lead to poor decisions. It’s vital to evaluate suppliers based on their delivery track record.

Communication also plays a key role. Are your suppliers transparent about potential delays? If not, this lack of communication can complicate operations. Regular updates are necessary to adjust plans accordingly. Without a reliable partner, the consequences can ripple throughout the organization. Reflecting on these challenges can provide insight into improving supplier relationships.

| Supplier Type | Average Delivery Time (Days) | Reliability Score (%) | On-Time Delivery Rate (%) | Cost Index (1-10 scale) |

|---|---|---|---|---|

| Local Supplier | 5 | 95 | 90 | 6 |

| National Supplier | 8 | 90 | 85 | 7 |

| International Supplier | 15 | 85 | 80 | 8 |

| Small-Scale Supplier | 6 | 88 | 88 | 9 |

| OEM Supplier | 10 | 92 | 82 | 7 |

Building long-term partnerships with mechanical parts suppliers is crucial for sustainable success. Trust and communication are the foundations. When suppliers understand your specific needs, they can deliver better solutions. This connection often leads to flexibility during urgent requests.

Effective communication is key. Regular meetings can help align goals and expectations. Share feedback openly. This helps both sides improve. Suppliers appreciate knowing how their products perform.

Tips: Establish clear metrics for performance evaluation. This aids in identifying areas needing improvement. Invest time in relationship building. A strong bond can lead to better pricing and priority service. Remember, every partnership has challenges. Adjustments are necessary for growth. Embrace changes as opportunities.