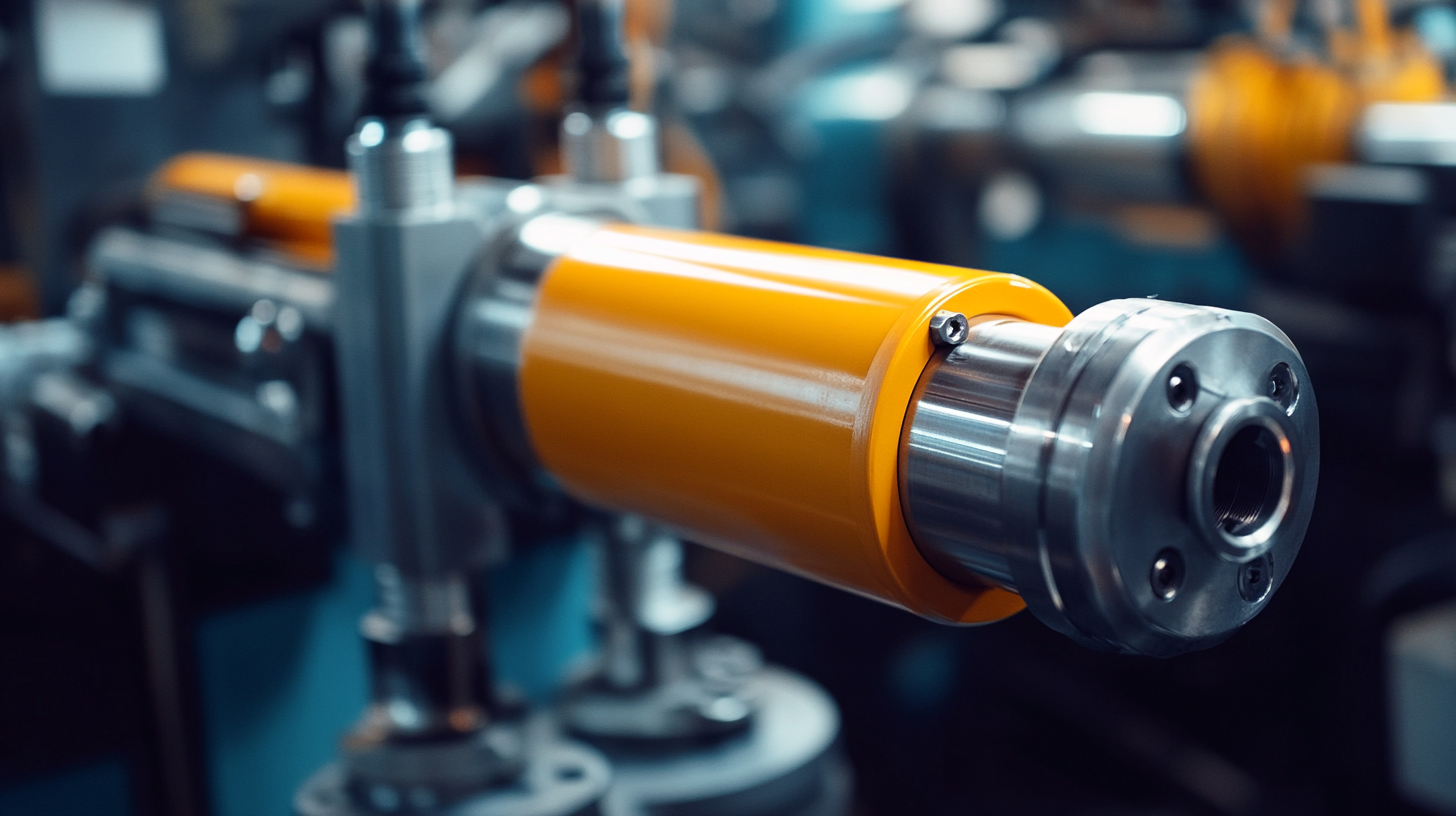

Choosing the right hydraulic cylinder for your industrial needs can significantly impact the efficiency and productivity of your operations. Hydraulic cylinders are essential components in various machinery and equipment, providing the power needed to lift, push, or pull heavy loads with precision. However, with the myriad of options available in the market, selecting the most suitable hydraulic cylinder for your specific application can be a daunting task. Factors such as size, stroke length, mounting style, and material should all be carefully considered to ensure optimal performance and longevity. In this blog, we will guide you through the key elements to evaluate when selecting a hydraulic cylinder for your industrial requirements, empowering you to make an informed decision that meets both your operational goals and budget constraints.

When selecting the right hydraulic cylinder for industrial applications, it’s essential to understand the various types available and their specific uses. Hydraulic cylinders are typically categorized into several types, including single-acting and double-acting cylinders, tie rod, and welded cylinders. Each type serves distinct purposes, from simple lifting tasks to complex positioning in automated machinery. According to a recent industry report, the demand for hydraulic cylinders is projected to grow by approximately 5.3% annually, driven by advancements in lightweight hydraulic components that enhance performance in mobile applications.

Moreover, innovations like the SICK DAX Linear Encoder have significantly improved the precision of piston position detection in hydraulic systems, offering manufacturers the ability to optimize their processes. As the industry embraces advanced automation solutions, understanding the interplay between hydraulic and electric actuators becomes increasingly critical. Although electric actuators are gaining traction due to their efficiency and reduced maintenance needs, the hydraulic sector remains strong, bolstered by positive market conditions in manufacturing and heavy equipment. Reports indicate that the fluid power sector will continue to thrive in the coming years, making the selection of the right hydraulic cylinder crucial for meeting evolving industrial demands.

When selecting the right hydraulic cylinder for industrial applications, it is crucial to consider key factors that can impact performance and reliability. According to Vantage Market Research, the hydraulic cylinder market is projected to experience significant growth, reaching a valuation of approximately $13 billion by 2035, with a compound annual growth rate (CAGR) of around 5.8% from 2025 to 2034. This growth underscores the increasing demand for advanced hydraulic systems across various sectors, including construction, manufacturing, and automotive.

One of the most important factors to consider when choosing a hydraulic cylinder is the application it will serve. Different applications require different specifications, such as stroke length, bore size, and pressure ratings. Additionally, the material and design of the cylinder must be suited to the operating environment—be it harsh chemicals or extreme temperatures. Recent trends show a growing inclination toward lightweight materials and innovative designs that enhance efficiency and durability, which reflects a broader movement in the hydraulics industry towards optimization and sustainability. By carefully evaluating these factors, businesses can ensure they select cylinders that not only meet current demands but also adapt to future industrial needs.

When selecting a hydraulic cylinder for your industrial applications, evaluating load capacity and performance requirements is crucial. The load capacity directly influences the efficiency and safety of your operations. Begin by determining the maximum load the cylinder will need to lift or move. It's essential to factor in not only the static load but also any dynamic forces that may occur during operation, such as inertia and shock loads.

Tip: Always consult the manufacturer's specifications and guidelines to ensure the hydraulic cylinder can handle the expected load with a suitable safety factor—typically, a factor of 1.5 to 2 is recommended.

Additionally, consider the performance requirements, such as stroke length and operating speed. These aspects determine how efficiently the system will perform in real-world conditions. Look for cylinders that offer adjustable speed options if your application requires precise control over the movement.

Tip: Perform a thorough analysis of your application's cycle time and necessary speed to ensure the cylinder can meet your requirements without strain. Prioritizing these factors will help you choose a high-quality hydraulic cylinder that enhances productivity and reliability in your industrial processes.

When selecting a hydraulic cylinder for industrial applications, the importance of material and design cannot be overstated. The material chosen directly affects the cylinder's performance, durability, and ability to withstand harsh operating conditions. For instance, materials with a high young's modulus can provide increased strength and rigidity, essential for high-power actuation in safety-critical environments. When assessing materials, it’s crucial to evaluate their resistance to fatigue, corrosion, and wear, especially for applications that involve extensive load cycles or exposure to aggressive environments.

Additionally, the design of the hydraulic cylinder plays a pivotal role in its efficiency and effectiveness. Factors such as the geometry, seal type, and overall configuration must be optimized to ensure optimal fluid dynamics and minimize pressure losses. Innovative approaches like Design for Additive Manufacturing (DfAM) have emerged, allowing for more complex geometries that can enhance performance characteristics while reducing material waste. By integrating intelligent design principles into the selection process, manufacturers can significantly improve the functionality and reliability of hydraulic cylinders, thereby meeting the demanding needs of various industrial sectors.

Maintaining hydraulic cylinders is crucial for ensuring their performance and longevity in industrial applications. According to a report by the International Institute of Hydraulic Systems, regular maintenance can extend the life of hydraulic cylinders by up to 30%. One of the key practices is to routinely check for leaks and signs of wear, especially on seals and O-rings. A small leak can significantly affect the performance and efficiency of the hydraulic system, leading to costly repairs and replacements.

Another vital maintenance tip is to keep the hydraulic fluid clean and at the proper level. Contaminated fluid can cause increased abrasion and corrosion, which can lead to premature failure of the cylinder. The National Fluid Power Association recommends changing hydraulic fluid annually or as per the manufacturer’s guidelines to prevent deposits and maintain optimal system functionality. Additionally, performing regular inspections of the cylinder's mounting and alignment can help avoid misalignment issues that can result in uneven wear and tear, ultimately prolonging the lifecycle of your hydraulic equipment.