In today's competitive manufacturing landscape, sourcing high-quality custom cylinders is crucial for businesses aiming to optimize their operations and enhance product offerings. With the phrase "Focus on quality, China manufacturing, leading global exports" resonating strongly in the industry, many companies are turning to China for their manufacturing needs. This guide aims to provide an in-depth exploration of the factors to consider when sourcing custom cylinders, highlighting the importance of quality, reliability, and the robust capabilities of Chinese manufacturers. By understanding the nuances of customization and the benefits of partnering with renowned suppliers, businesses can ensure they are equipped with the best custom cylinders to meet their specific requirements and drive success in the global market. Join us as we delve into the definitive handbook for sourcing the best custom cylinder for your business.

When sourcing custom cylinders for your business, understanding industry standards is essential for ensuring quality and compliance. Recent reports indicate a growing focus on eco-friendly and energy-efficient solutions across various sectors, which influences the hydraulic cylinder market's trajectory. A projected shift towards greener technologies is expected to augment market outlooks significantly between 2025 and 2034, highlighting the importance of adhering to current environmental standards during the manufacturing process.

Moreover, industry leaders are recognizing the significance of innovation in custom fabrication. For instance, advancements in rapid custom rubber 3D printing are enabling manufacturers to offer customizable solutions while meeting standard industrial specifications. This trend underscores the necessity for businesses to remain agile and responsive to evolving industry standards, as seen in initiatives such as Transport Canada's recent updates to packaging standards for gas containers in pressure vessels. Staying informed and compliant with such standards not only enhances operational efficiency but also fosters trust and safety in customer relationships.

When sourcing custom cylinders for your business, there are several key factors to consider that can significantly impact your operational efficiency and profitability.

One of the foremost considerations is the material used in the cylinder's construction.

Selecting the right material not only affects performance but also durability, corrosion resistance, and maintenance needs.

It's essential to align the material properties with the specific requirements of your application to ensure long-term reliability.

Another critical aspect is the customization options available from manufacturers.

Different industries have unique demands, and the ability to tailor cylinder dimensions, pressure ratings, and other specifications becomes crucial.

Engaging with suppliers that offer a broad range of customizable features can help meet specific operational needs while also adhering to industry standards.

Finally, understanding the market trends, including the projected growth of the hydraulic equipment sector, with an expected size worth USD 52.6 billion by 2033, can help businesses make informed decisions and secure a competitive edge.

By focusing on these vital factors, companies can effectively source the best custom cylinders to optimize their operations.

In today’s rapidly evolving manufacturing landscape, digital innovations are reshaping the production of custom cylinders. Technologies such as 3D printing and advanced CNC machining are revolutionizing how businesses approach the creation of tailored cylinder solutions. These methods enable manufacturers to produce complex geometries with precise specifications, significantly reducing lead times and production costs. As companies seek to streamline their operations, the shift towards digital methods enhances efficiency and encourages responsive design adjustments, ensuring that the final product aligns perfectly with customer expectations.

Moreover, the integration of data analytics and IoT (Internet of Things) in the manufacturing process allows for real-time monitoring and optimization. By leveraging smart technologies, producers can track performance metrics, identify potential issues before they escalate, and maintain high-quality standards throughout the production cycle. These digital advancements not only improve production workflows but also foster better collaboration between manufacturers and clients, enabling businesses to provide bespoke cylinder solutions that meet specific functional requirements. Ultimately, embracing these technological strides is essential for any company looking to stay competitive in the custom cylinder market.

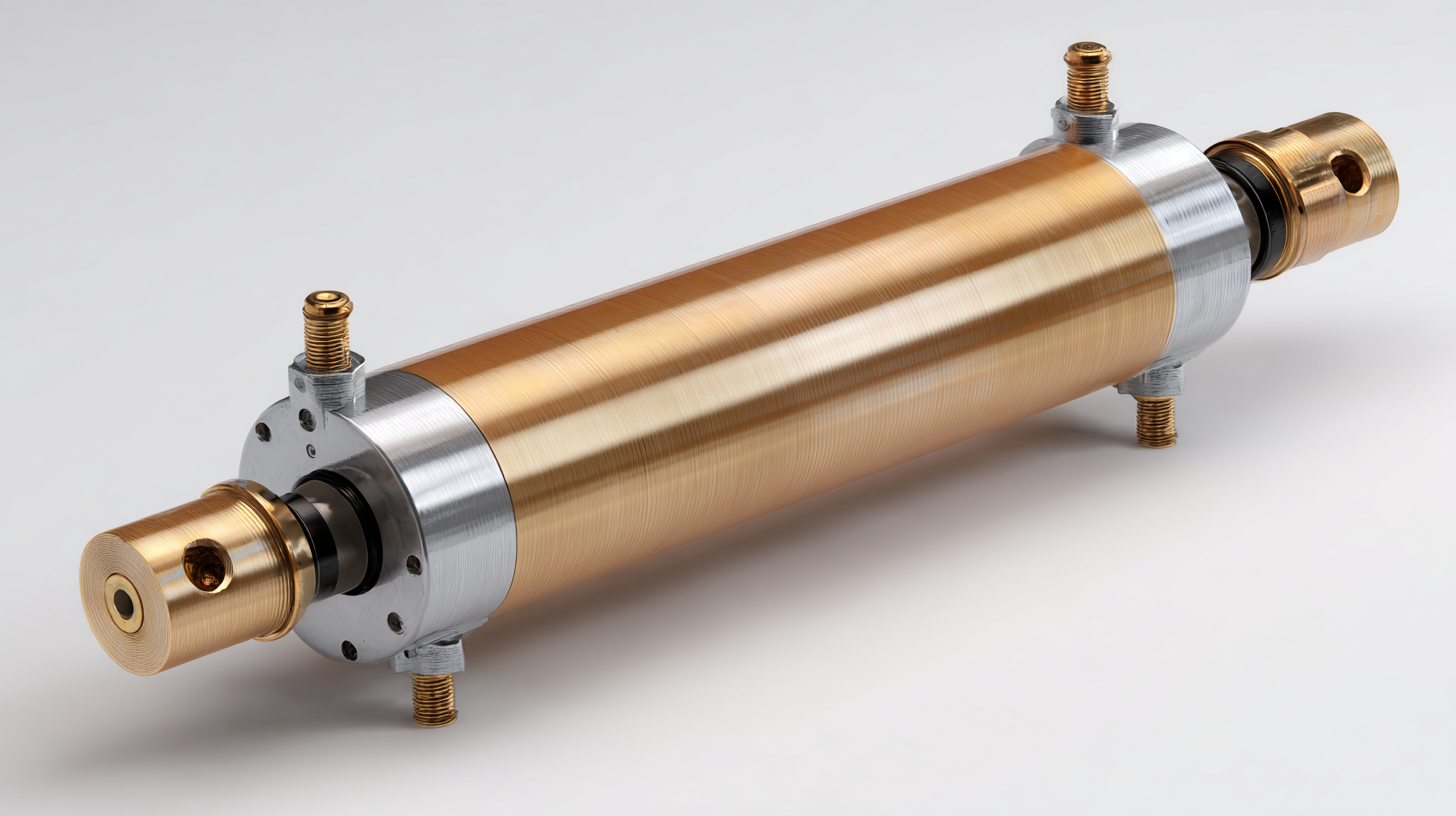

When selecting the ideal custom cylinder for your business, understanding the various types available is crucial. Custom cylinders can generally be categorized into two main types: hydraulic cylinders and pneumatic cylinders. Hydraulic cylinders utilize pressurized fluid to generate power, making them suitable for heavy-duty applications requiring high force transmission. They are commonly found in construction and manufacturing equipment, where strength and reliability are paramount. On the other hand, pneumatic cylinders operate using compressed air, making them ideal for lighter applications. They offer faster action and are often utilized in packaging, assembly lines, and other automated processes where speed is essential.

Furthermore, within these categories, there are specialized options such as tie rod cylinders, welded cylinders, and double-acting cylinders. Tie rod cylinders are preferred for their modular design, allowing for easy maintenance and customization. Welded cylinders, known for their durability and robustness, are often used in demanding environments. Meanwhile, double-acting cylinders provide versatility by enabling motion in both directions, making them highly adaptable for various applications. By understanding the specific characteristics and applications of these cylinder types, businesses can make informed decisions that align with their operational needs and enhance overall efficiency.

When sourcing custom cylinders for your business, the temptation to

prioritize cost over quality can be strong.

However, choosing quality materials and

manufacturing processes can significantly impact your operational efficiency and product performance.

High-quality cylinders are often engineered to meet stringent industry standards,

leading to enhanced durability and reliability. This reduces the

likelihood of failures that could result in costly downtime or safety hazards, ultimately saving your

business money in the long run.

Moreover, investing in quality custom cylinders can improve overall product satisfaction

and customer trust. When your products perform better and demonstrate longevity, customer loyalty increases, leading to repeat business and positive referrals.

In competitive markets, maintaining a reputation for quality

can set your business apart, making it essential to view cylinder sourcing as a long-term investment

rather than a short-term expense. By committing to quality, you not only bolster your operations but

also pave the way for sustainable growth and success.