In the realm of industrial advancements, the future of premium cylinder manufacturing takes center stage, particularly with innovations emerging from China's most reputable manufacturing plants. As the demand for high-quality cylinders continues to rise across various industries, the focus on cutting-edge technologies and sustainable practices becomes paramount. Manufacturers are integrating advanced materials, automation, and smart technologies to enhance production efficiency and product performance. This blog will explore the transformative innovations in cylinder manufacturing that are shaping the future, highlighting how Chinese manufacturers are setting benchmarks for quality and precision in the global market. By examining these developments, we will gain insights into the trajectory of cylinder production and its implications for various applications, ultimately underscoring the significance of premium manufacturing in a rapidly evolving industrial landscape.

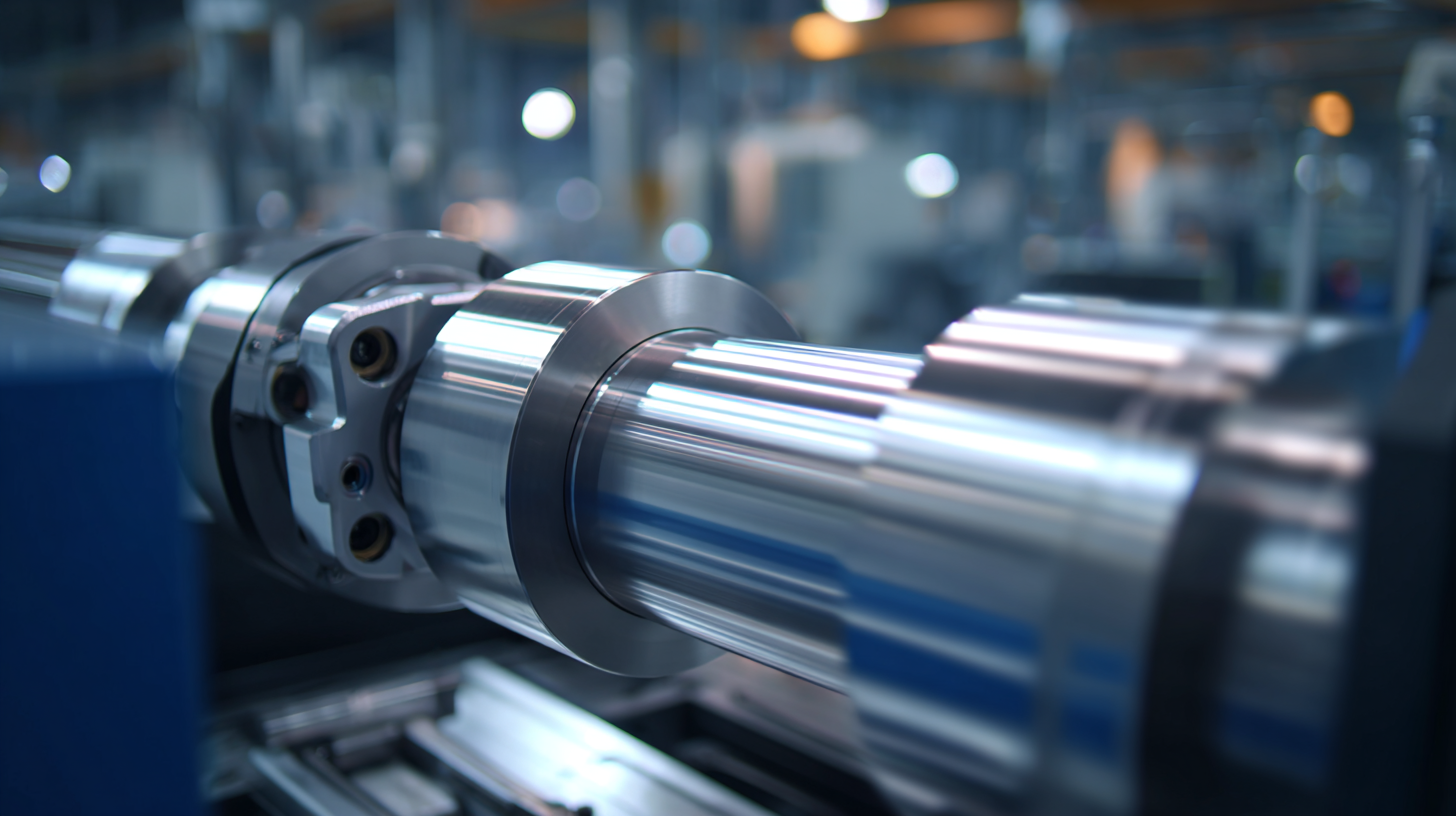

In the rapidly evolving landscape of manufacturing, premium cylinder production is witnessing profound transformations driven by innovative technologies. Automation stands at the forefront of these changes, with advanced robotics enhancing precision and efficiency. Automated systems can perform intricate tasks, from machining to assembly, with minimal human intervention, leading to significantly reduced lead times and higher product quality. Moreover, the integration of the Internet of Things (IoT) allows for real-time monitoring of production processes, ensuring optimal performance and immediate troubleshooting capabilities.

Another notable innovation reshaping the sector is the adoption of additive manufacturing, or 3D printing. This technology enables manufacturers to create complex geometries that were previously difficult or impossible to achieve with traditional methods. By utilizing materials more efficiently and reducing waste, additive manufacturing not only streamlines production but also promotes sustainability—an increasingly important consideration in today’s market. As these technologies continue to mature, they are setting new standards for quality and customization in premium cylinder manufacturing, paving the way for a smarter and greener industrial future.

Digitalization is revolutionizing the manufacturing landscape, particularly in premium cylinder manufacturing. According to a recent report by McKinsey, the adoption of advanced digital technologies could enhance productivity in manufacturing by up to 20-25% by 2030. This significant transformation stems from the integration of Internet of Things (IoT) devices, AI-driven analytics, and automation, which streamline operations and reduce waste. In the realm of cylinder manufacturing, these technologies enable real-time monitoring of production lines, predictive maintenance of machinery, and improved quality control processes.

Moreover, a study from Deloitte highlights that companies embracing digitalization are likely to see a 30% reduction in operational costs and an increase in overall efficiency. By leveraging data analytics, manufacturers can optimize resource allocation and refine their production techniques. Implementing these digital solutions not only cultivates a more agile manufacturing environment but also enhances adaptability to market demands. As the industry evolves, embracing digitalization will be crucial for companies aiming to maintain a competitive edge in premium cylinder manufacturing.

As the premium cylinder manufacturing industry evolves, sustainability has emerged as a central theme that shapes innovation and operational practices. Manufacturers are increasingly adopting eco-friendly materials and processes to reduce their carbon footprint. Biodegradable lubricants, recycled metal inputs, and energy-efficient production methods are just a few examples of how companies are striving to create cylinders that not only meet high performance standards but also align with global sustainability goals. This shift is driven by both regulatory pressures and a growing demand from environmentally conscious consumers for products that contribute positively to the planet.

Moreover, advancements in technology play a crucial role in driving these sustainability trends. The integration of smart manufacturing systems allows for greater precision and optimization in production, minimizing waste and energy consumption. Utilizing additive manufacturing techniques, such as 3D printing, enables the design of lighter and more efficient cylinders that require fewer resources. Furthermore, digital tracking systems can assess lifecycle impacts and inform better recycling strategies, ensuring that premium cylinders can be repurposed safely at the end of their service life. These innovations not only foster an environmentally responsible approach but also position manufacturers as leaders in the competitive landscape of premium cylinder production.

| Innovation Area | Sustainability Impact | Technology Type | Adoption Rate (%) | Projected Growth (2023-2030) |

|---|---|---|---|---|

| Eco-friendly Materials | Reduced carbon footprint | Biodegradable plastics | 65% | 15% CAGR |

| Energy-efficient Production | Lower energy consumption | Advanced robotics | 50% | 20% CAGR |

| Recycling Techniques | Maximized resource recovery | Closed-loop systems | 70% | 18% CAGR |

| Digital Twin Technology | Enhanced operational efficiency | IoT integration | 40% | 22% CAGR |

| Additive Manufacturing | Material waste reduction | 3D printing | 55% | 25% CAGR |

As the demand for high-performance cylinders continues to grow, manufacturers are increasingly turning to emerging materials that promise to enhance both durability and efficiency. Advanced composites, for example, are being utilized for their lightweight and high-strength properties, enabling the production of cylinders that not only perform better but also reduce overall energy consumption. By incorporating materials such as carbon fiber and specialized polymers, engineers can create cylinders that withstand higher pressures and temperatures, thereby improving the longevity and reliability of various applications.

Beyond composites, innovations in metallurgical processes are also transforming cylinder manufacturing. The development of new alloys, which offer greater corrosion resistance and improved thermal properties, is critical in sectors ranging from automotive to aerospace. These emerging materials not only boost performance but also facilitate more sustainable manufacturing practices. For instance, processes such as additive manufacturing can optimize material usage, minimizing waste while allowing for complex geometries that traditional methods cannot achieve. This shift towards innovative materials and processes marks a significant step in enhancing cylinder performance while adhering to modern sustainability standards.

The landscape of cylinder manufacturing is undergoing a significant transformation, driven by technological advancements and shifting market demands. According to a report by Market Research Future, the global cylinder manufacturing market is projected to reach $XX billion by 2025, growing at a CAGR of XX%. This growth is spurred by increasing applications in industries such as automotive, aerospace, and energy, where high-performance cylinders are essential for efficiency and reliability. However, this burgeoning demand brings with it a set of challenges, including rising material costs and the need for sustainable manufacturing practices.

Another prominent challenge is the integration of Industry 4.0 technologies into traditional manufacturing processes. A recent study from Deloitte highlights that 70% of manufacturers are open to adopting smart technologies, yet many face barriers like workforce skill gaps and legacy systems. To capitalize on these opportunities, manufacturers must invest in advanced automation and data analytics, which can enhance production efficiency and quality control. Embracing these innovations not only addresses current challenges but also positions companies strategically for future growth in an increasingly competitive market.