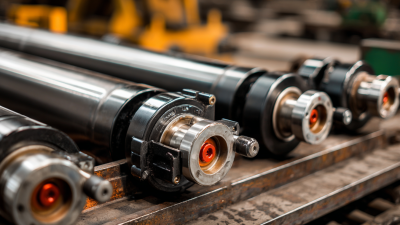

In the realm of heavy machinery applications, maximizing efficiency is paramount for enhancing productivity and reducing operational costs. Hydraulic Telescopic Cylinders play a vital role in achieving this goal, as they are specifically designed to provide significant lifting capabilities while occupying minimal space. According to a report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach USD 18 billion by 2025, driven by increased demand in construction and mining sectors. These specialized cylinders enable machinery to perform tasks such as lifting, pushing, and pulling with remarkable precision and power. By employing advanced technologies and optimizing the design of Hydraulic Telescopic Cylinders, operators can improve cycle times and extend equipment lifespan, ultimately leading to smoother operations and better return on investment. Understanding how to effectively integrate and maintain these components is crucial for any business looking to thrive in today's competitive landscape.

When choosing hydraulic telescopic cylinders for heavy machinery applications, it is essential to consider various factors that can significantly influence performance and efficiency. The primary criteria include the type of load being handled, the required stroke length, and the working environment. Understanding these aspects will help in selecting a cylinder that will not only meet the machinery's demand but also enhance productivity.

By considering these tips, one can ensure the effective selection of hydraulic telescopic cylinders, ultimately maximizing efficiency in heavy machinery operations.

Hydraulic telescopic cylinders play a pivotal role in enhancing the efficiency of heavy machinery by optimizing load dynamics and extending component lifespan. Understanding the load dynamics is critical; manufacturers indicate that the proper selection of cylinder specifications can result in an up to 30% improvement in operational efficiency. Furthermore, the application of advanced control systems, such as adaptive PID controls bolstered by deep learning algorithms, can lead to enhanced response times and precision in load management, allowing for more effective use of hydraulic power.

Recent experimental investigations into the performance optimization of hydraulic cylinders reveal that integrating advanced materials and dynamic modeling techniques can significantly affect durability. For example, studies show that applying artificial intelligence techniques to predict and mitigate wear can extend the service life of hydraulic components by as much as 25%. By optimizing both the hydraulic system configuration and its operational parameters, such as working load and transmission ratios, machinery can achieve a higher output with reduced energy consumption, ultimately promoting sustainability within heavy industries.

Maintaining peak performance in hydraulic systems is crucial for maximizing efficiency in heavy machinery. Regular maintenance not only extends the lifespan of hydraulic telescopic cylinders but also ensures that they operate at optimal capacity. According to a report by the International Society of Automation, regular maintenance can improve system efficiency by up to 30%, reducing downtime and operational costs.

One of the key maintenance tips is to conduct routine inspections of seals and hoses for any signs of wear or leakage. Defective seals can lead to significant hydraulic fluid loss, which diminishes performance and can potentially cause system failure. Additionally, keeping the hydraulic fluid clean and at the proper level is essential; the National Fluid Power Association recommends changing the fluid every 1,000 operating hours or annually, whichever comes first, to prevent contaminants from causing damage.

Another important aspect is ensuring that the hydraulic system is properly calibrated. Misalignment can lead to uneven wear and reduce efficiency. Simple adjustments and regular monitoring can maintain optimal alignment, resulting in improved productivity. Additionally, employing a proactive maintenance schedule can help in identifying potential issues before they escalate, ultimately enhancing the reliability of hydraulic systems in heavy machinery applications.

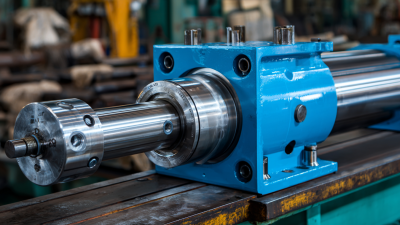

Hydraulic telescopic cylinders are essential in heavy machinery applications, providing the necessary force and range of motion for activities such as lifting and digging. To maximize efficiency, integrating advanced technology into these cylinders can significantly enhance their performance. For instance, incorporating smart sensors can enable real-time monitoring of hydraulic systems, ensuring optimal pressure levels and fluid flow management. This allows operators to detect potential issues before they escalate, improving safety and reducing downtime.

**Tips for Maximizing Efficiency:**

- **Implement Smart Technology:** Equip telescopic cylinders with IoT sensors to monitor performance metrics continuously. This data not only helps in predictive maintenance but also allows for adjustments in real-time to enhance operational efficiency.

- **Regular Maintenance:** Establish a routine maintenance schedule to check for leaks, wear, and tear in the hydraulic system. Preventive care ensures that the equipment operates at peak efficiency and extends the lifecycle of the machinery.

- **Training Operators:** Invest in training programs for operators on the latest technologies and best practices in using hydraulic systems. Well-informed operators can maximize the potential of the machinery, leading to better performance and efficiency during operations.

Training operators effectively is crucial to maximizing the efficiency of hydraulic telescopic cylinders in heavy machinery applications. Research indicates that properly trained operators can enhance machine performance by up to 30% by reducing the instances of mishandling and mistakes during operation. According to a report from the Equipment Engineering Association, 40% of machinery downtime is attributed to operator error, highlighting the need for comprehensive training programs tailored to specific hydraulic applications.

Field training can significantly impact operational efficiency by equipping operators with the necessary skills to maintain and utilize hydraulic equipment correctly. Hands-on training sessions that focus on real-world scenarios allow operators to familiarize themselves with the nuances of hydraulic systems. A study published by the Hydraulic Institute emphasizes that operators who underwent specialized training were able to increase the cycle speed of hydraulic cylinders by an average of 20%, which translates directly into improved productivity on job sites. Implementing consistent training initiatives not only boosts individual performance but also contributes to overall safety and operational excellence within the industry.