A Roll Lamination Machine is an innovative tool used to enhance the durability of various materials. This machine applies a protective layer of film over surfaces, making them resistant to wear and tear. With its increasing popularity, many industries rely on this technology for better product quality.

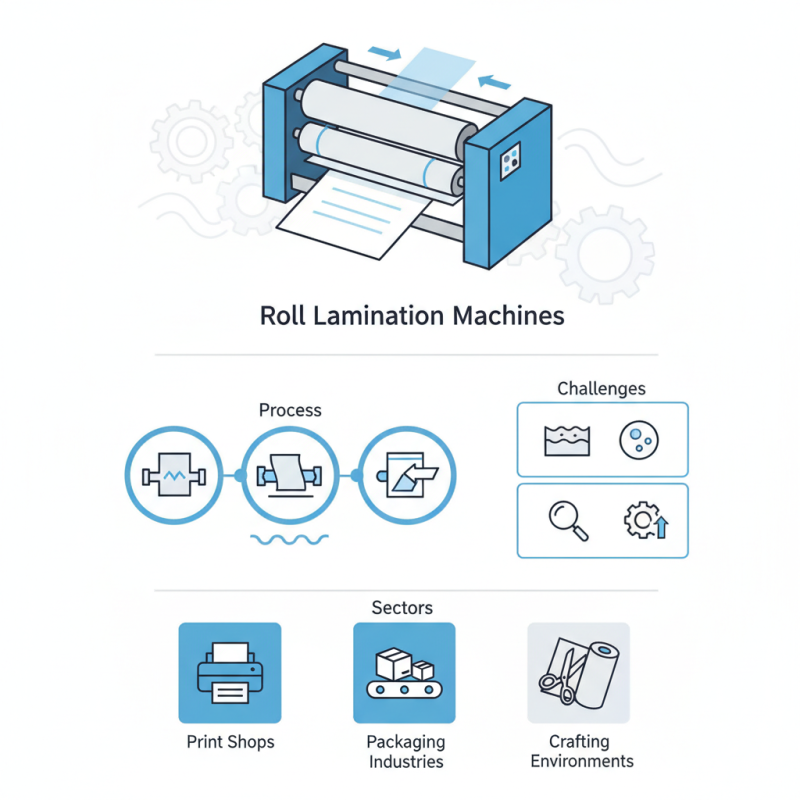

The process begins with feeding the material into the machine. Rollers press a lamination film onto the surface, ensuring a tight bond. The machine’s precision is crucial. However, issues may arise, such as uneven application or bubbles under the film. Operators must closely monitor these aspects for optimal results.

The Roll Lamination Machine serves multiple sectors. It can be found in print shops, packaging industries, and even crafting environments. Each application offers unique challenges. Users need to reflect on their methods and consider improvements for efficiency. Understanding its functionality can lead to better practices in lamination.

A roll lamination machine is an essential tool in various industries. It uses heat and pressure to bond materials together. This process can create a protective layer on products, enhancing their durability. Typically, it handles flexible materials like films or sheets.

The primary function involves rolling the material through heated rollers. The heat activates the adhesive properties of the laminate. This results in a strong, seamless bond. Operators need to ensure proper temperature and pressure settings. Inconsistent settings can lead to weak adhesion or material damage. It's important to regularly check the machine’s performance to avoid unexpected flaws.

While the process is mostly efficient, challenges can arise. Misalignment during rolling may cause wrinkles or bubbles. These issues can compromise the final product's quality. Continuous monitoring and adjustments are crucial. Additionally, thorough training for operators is necessary. Without proper knowledge, even a small mistake can result in wasted materials and time.

A roll lamination machine is vital for various industries. It applies layers of material for added durability. One of the key components is the roller system. The rollers exert pressure, ensuring uniform lamination. They come in different sizes, depending on material thickness. Proper alignment is crucial here. Misalignment can lead to uneven laminates.

Another important part is the feed mechanism. It guides the material into the machine smoothly. If the feed is inconsistent, it can cause jams. Regular maintenance is essential to prevent this. Sensors can help detect problems early. They alert operators to potential issues, reducing downtime.

Finally, there’s the heating unit. It activates the adhesive between layers. Too much or too little heat can be problematic. It’s a delicate balance. Operators must monitor the temperature closely. This ensures the best bonding quality. Each component plays a significant role. When they work together, the results can be impressive. Yet, there’s always room for improvement in the process.

Roll lamination is a fascinating process. It involves layers of paper or film being bonded together using heat and pressure. This machine has become essential in various industries. Many rely on it for packaging and printing. According to a recent industry report, the global laminating machine market is projected to reach $1.38 billion by 2027, highlighting its significance.

The operation of a roll lamination machine typically follows a series of steps. Materials are first pulled from large rolls. The machine then applies adhesive on one side of the material. After that, it passes through heated rollers. These rollers press the materials together, ensuring a solid bond. The temperature and pressure must be carefully monitored. A small mistake in settings can lead to poor results. Sometimes, the layers may not adhere properly, resulting in waste.

After lamination, the finished product is cooled and cut to size. It is then ready for distribution. Monitoring production efficiency can be challenging. Quality control is often inconsistent. This can affect the final output. Many companies invest in training their operators. This is essential to minimize errors. However, with growing demands, some facilities still struggle to maintain high standards.

Roll lamination machines play a crucial role in various industries. They are widely used in packaging, labels, and textiles. These machines combine layers of materials using heat and pressure. This process creates a strong bond, resulting in durable products. The efficiency of roll lamination is vital for meeting production demands. Many industries are leveraging this technology to improve output while reducing costs.

Recent statistics show a growing trend in the usage of roll lamination. Many companies are investing in advanced machines. This shift reflects the need for high-quality products. The packaging industry alone has seen a significant increase in efficiency. However, challenges remain. Not every operation has adapted to the latest technologies. Companies must evaluate their processes. Identifying gaps can lead to better performance and innovation. Embracing change is essential for staying competitive in the market.

| Application | Industry | Market Share (%) | Growth Rate (%) | Key Trends |

|---|---|---|---|---|

| Packaging | Food & Beverage | 35 | 5 | Eco-friendly materials, convenience |

| Thermal Laminating | Printing and Publishing | 25 | 4.2 | Personalized printing, high gloss |

| Industrial Laminating | Construction | 20 | 3.5 | Sustainability, energy efficiency |

| Protective Coating | Automotive | 10 | 6.1 | Durability, scratch resistance |

| Graphic Lamination | Advertising | 10 | 7.3 | Digital signage, vibrant colors |

Roll lamination machines are crucial in modern manufacturing. They provide a simple yet effective way to bind materials together. By applying heat and pressure, they ensure durability. This method creates a strong bond while maintaining the integrity of the materials. The process is quick and efficient, making it ideal for large-scale production.

One significant advantage of roll lamination machines is their versatility. They can handle various materials, including plastic films and papers. This adaptability allows manufacturers to produce a wide range of products. Furthermore, the machines enhance the appearance of finished goods. Laminated products often look more polished and professional. However, achieving the perfect finish requires careful calibration and regular maintenance. It’s easy for small misalignments to occur, leading to imperfections.

Cost efficiency is another benefit of using roll lamination machines. They reduce waste by utilizing materials effectively. When running smoothly, they can save time and resources. Yet, operators must remain vigilant. Errors or equipment failures can lead to costly downtime. Investing in employee training can mitigate these risks. The balance between efficiency and oversight is essential for overall success in laminate production.