In the world of industrial machinery, choosing the right hydraulic cylinders, or hyd cylinders, is critical for ensuring operational efficiency and safety. According to a recent market analysis by ResearchAndMarkets, the global hydraulic cylinder market is expected to reach $18.7 billion by 2025, growing at a CAGR of 4.2%. This growth underscores the importance of selecting high-quality hyd cylinders tailored to specific applications within your business.

Industries ranging from construction to manufacturing increasingly depend on these essential components to facilitate power transmission and enhance productivity. As the demand for precision and reliability intensifies, understanding the key factors involved in selecting the appropriate hyd cylinders becomes pivotal for business owners seeking to optimize their equipment and processes.

In this blog, we will explore seven ultimate tips that will guide you in making informed decisions when choosing hyd cylinders that meet your unique business needs.

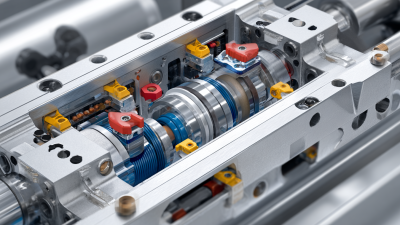

When selecting hydraulic cylinders for your business, it’s crucial to understand the basic features that accommodate your specific needs. Start by considering the application of the hydraulic cylinders; they are essential in various industries, including auto transport, where heavy machinery and vehicles must be moved efficiently. Identifying the required specifications, such as bore size, stroke length, and working pressure, will ensure that you choose cylinders that can withstand the demands of your operations.

Additionally, evaluate the materials and construction of the hydraulic cylinders. Durability is paramount, especially in industries involving heavy lifting or rough environments. Look for cylinders made from high-quality materials that offer resistance to wear and corrosion. It's also beneficial to consider the maintenance requirements associated with different hydraulic systems. A well-maintained hydraulic cylinder not only enhances efficiency but also reduces downtime, which is critical when transporting millions of vehicles each year. Investing time in understanding these basics will empower you to make informed decisions that align with your operational goals.

When selecting hydraulic cylinders for your business, understanding the specifications is crucial to ensure optimal performance. Key factors such as stroke length, diameter, and pressure ratings can significantly impact the efficiency of your equipment. The stroke length defines how far the cylinder can extend and retract, affecting the range of motion necessary for your applications. To choose the correct stroke length, assess the operational needs and the physical constraints of your machinery.

In addition to stroke length, the diameter of the cylinder plays a vital role in determining the force output. A larger diameter generally allows for greater force generation, but it also comes with increased weight and size considerations. You must balance the need for power with the spatial limitations of your equipment. Lastly, understanding the pressure ratings is essential; ensure that the selected cylinders can withstand the maximum operational pressure without compromising safety or performance. Evaluating these specifications thoroughly will help you choose the right hydraulic cylinders tailored to your business's unique demands.

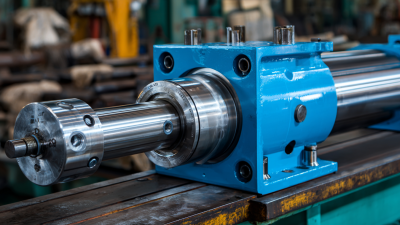

When selecting hydraulic cylinders for your business, the material used in their construction is a critical factor that can significantly impact their longevity and durability. High-quality materials not only enhance the performance of hydraulic systems but also reduce maintenance costs over time. For industrial applications, steel is often favored due to its strength and resistance to wear and tear. Additionally, stainless steel provides excellent corrosion resistance, making it ideal for environments exposed to moisture or chemicals.

Another important consideration is the use of composite materials. These materials can be engineered to provide exceptional strength-to-weight ratios, which can enhance efficiency and reduce energy consumption in hydraulic applications. Moreover, composite hydraulic cylinders are less susceptible to corrosion and fatigue, ensuring a longer service life. By evaluating the materials used in hydraulic cylinder construction, businesses can make informed decisions that ultimately contribute to their operational reliability and cost-effectiveness. Choosing the right materials not only supports performance but also aligns with sustainability goals by minimizing waste and extending equipment lifespan.

| Tip | Material | Durability Rating | Applications | Maintenance Requirement |

|---|---|---|---|---|

| 1. Evaluate Your Needs | Steel | High | Heavy machinery | Low |

| 2. Consider Operating Environment | Aluminum | Medium | Outdoor applications | Medium |

| 3. Check for Corrosion Resistance | Stainless Steel | Very High | Food processing | Minimal |

| 4. Assess Weight and Size | Composite | High | Aerospace | High |

| 5. Verify Manufacturer Reputation | Iron | Medium | Construction | Low |

| 6. Price vs Performance | Carbon Steel | Medium | Automotive | Medium |

| 7. Ensure Compliance with Standards | Titanium | Very High | High-stakes industries | Medium |

Choosing the right hydraulic cylinders for your business can significantly impact operational efficiency, especially as industries increasingly leverage advanced technologies like AI. With the rise of industrial applications, selecting suitable cylinders tailored to specific uses is paramount. According to recent industry reports, the hydraulic cylinder market is expected to reach a value of $16 billion by 2025, emphasizing the importance of understanding application suitability.

One crucial tip is to analyze the specific demands of your industrial environment. Different machines require different types of cylinders based on factors such as load capacity, stroke length, and mounting style. For instance, a construction site may demand robust, high-pressure cylinders, while a manufacturing plant might focus on efficiency in smaller, more precise operations.

Additionally, consider the materials and conditions in which the cylinders will operate. Cylinders exposed to harsh environments need specialized coatings or materials to prevent corrosion and ensure durability. Keeping abreast of technological advancements, like AI-driven predictive maintenance, can further enhance performance and longevity, ensuring the hydraulic systems remain capable and efficient.

When it comes to maintaining hydraulic cylinders, proactive measures are essential to ensure their performance and longevity. Routine inspections are crucial; operators should regularly check for signs of wear, leakage, or corrosion. Addressing minor issues promptly can prevent costly repairs or system failures down the line.

Additionally, monitoring the hydraulic fluid quality is vital, as contaminated fluid can lead to increased wear on internal components, affecting the overall efficiency of the system.

Another critical aspect of cylinder maintenance is lubrication. Proper lubrication reduces friction, preventing premature wear and overheating. It’s important to follow the manufacturer’s guidelines regarding lubrication intervals and types of lubricants to use. Furthermore, operators should be trained to identify abnormal noises or vibrations during operation, as these can be early indicators of potential problems. By prioritizing these maintenance considerations, businesses can enhance the performance of their hydraulic cylinders and extend their operational lifespan, ultimately leading to greater productivity and reduced downtime.