In the industrial sector, the performance of the Overflow Valve Block is crucial for system efficiency. A malfunction can lead to severe operational disruptions. According to a recent industry report, 35% of equipment failures stem from valve-related issues. These failures often result in costly downtime and repairs.

Understanding the signs of failure in an Overflow Valve Block can save time and resources. Common symptoms include fluctuating pressure readings and unexpected flow interruptions. Addressing these problems early can enhance overall system reliability. However, many operators overlook these indicators until they escalate into major issues.

Regular maintenance is key. Yet, a survey showed that only 45% of companies schedule consistent checks on their Overflow Valve Blocks. Many users rely on reactive measures, which is not ideal. Ignoring these components can lead to greater complications in the system's performance. Being proactive instead of reactive is essential for long-term success and efficiency in any operation.

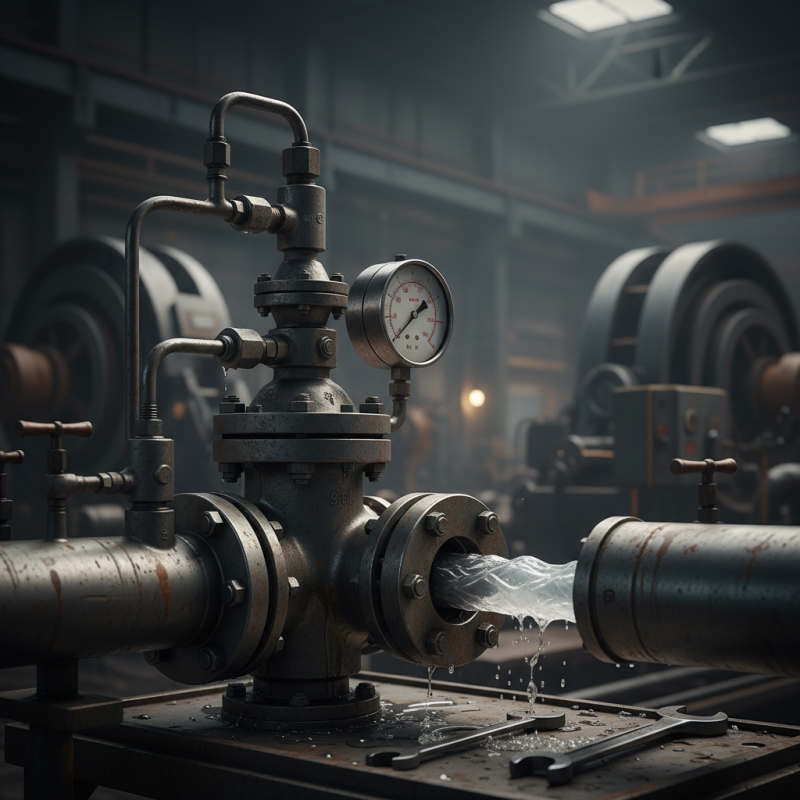

Identifying common symptoms of overflow valve block issues can help prevent major problems. One key sign is inconsistent pressure readings. If gauges fluctuate unexpectedly, it’s a red flag. Also, listen for unusual noises. Hissing or whistling sounds can indicate air leaks. These symptoms often signal a malfunctioning valve.

Another issue to watch for is slow response times. If the system takes longer to react, it may be due to blockages. Fluid should move smoothly. A noticeable delay can hinder overall performance. Occasionally, operators may notice fluid leaks around the valve area. This should not be ignored. It often means the valve is failing.

Visual inspections play a crucial role here. Look for signs of wear and tear. Inspecting connections and seals regularly can prevent future breakdowns. However, sometimes, issues might not be visible right away. They linger beneath the surface. Regular maintenance and monitoring can greatly reduce risks. Understanding these symptoms is a start but requires ongoing attention.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Leakage around the valve | Worn seals or gaskets | Replace seals or gaskets |

| Inconsistent pressure | Blockage in the valve | Inspect and clean the valve |

| Unusual noise from the valve | Air in the hydraulic system | Bleed the hydraulic system |

| Failure to open or close | Faulty actuator | Test and replace actuator if needed |

| Overheating | Excessive pressure or fluid viscosity | Check fluid levels and properties |

Overflow valves play a crucial role in various hydraulic systems. They help maintain pressure by releasing excess fluid when necessary. Understanding their mechanism is key to diagnosing issues effectively.

An overflow valve typically consists of a spring and a spool. When pressure exceeds a predetermined level, the spool moves. This movement opens a passage, allowing fluid to escape. Over time, wear and tear can affect the mechanism. The spring may weaken, leading to erratic behavior. Dust and debris can also clog the valve, hindering performance.

Regular maintenance is essential. Inspecting the valve for signs of wear is vital. Clean components can significantly improve efficiency. If pressure irregularities persist, it may indicate deeper issues. Reflection on the system's entire setup can provide insights. This helps ensure the overflow valve functions as intended.

Diagnosing overflow valve block issues requires careful observation and methodical steps. Start by inspecting the surrounding components. Look for signs of damage or wear. Signs include leaks or unusual noises. These can point to underlying problems. It's essential to pay attention to these details.

Next, check the pressure readings. Consistently low or high pressures indicate malfunction. Use a gauge for accuracy. Record the readings for reference. Sometimes, the issue may not be immediately clear. If an overflow valve isn’t functioning, it could be due to debris or internal faults. A thorough cleaning might be necessary.

Listening to the equipment can also provide clues. Unusual sounds may signal complications. Vibration levels might change, indicating issues. Engage your senses; observe how the system behaves under normal operation. Comparing these behaviors can help identify anomalies. Every detail counts in troubleshooting.

Troubleshooting overflow valve block issues can be challenging but rewarding. Effective repair techniques are crucial for ensuring safe and efficient operation. One common problem is increased pressure in the system. According to a recent industry report, nearly 30% of hydraulic system failures are linked to malfunctioning overflow valves. Understanding the root cause is vital for successful repairs.

Inspecting the valve for debris or obstructions is essential. Often, a simple cleaning can restore functionality. Regular maintenance can prevent buildup. A detailed analysis of the fluid flow should be conducted. Engineers recommend checking fluid viscosity. This can greatly impact the valve's performance. Inaccurate settings may lead to further complications. The average cost of downtime caused by overflow valve failure can reach thousands of dollars per hour.

Another technique involves recalibrating the valve. If the pressure remains unstable, consider adjusting the valve limits. This process requires precision and careful readings. Many technicians overlook this step, leading to recurring issues. In some cases, replacing the entire block may be necessary. While this option can be expensive, it may provide a long-term solution to ongoing problems. Neglecting these factors only prolongs inefficiency and raises operational costs.

Overflow valve issues can cause significant problems in fluid systems. Preventative measures are essential to avoid these complications. Regular inspections are crucial. Check for wear and tear in components such as seals and springs. Look for signs of leaks or corrosion. These issues can often escalate if not addressed early.

Proper maintenance routines are another key aspect. Clean the valve regularly to prevent blockage. Use appropriate lubricants on moving parts. Ensure that the valve is set to the correct pressure settings. Incorrect settings can lead to malfunction over time. Keep detailed records of inspections and maintenance activities. This helps identify patterns that may indicate potential issues.

Training personnel is also vital. Ensure that all operators understand how to monitor the system effectively. They should be able to recognize early warning signs of valve issues. Encourage an environment where team members report concerns promptly. Ignoring small problems can lead to bigger headaches down the road. Over time, these small practices can lead to a more reliable and efficient overflow valve system.